Insight to Our Strategy: Why direct BAYSE™ to the Hygiene Industry First?

Super Absorbent Polymer beads possess the remarkable ability to swell to well over 100 times their own weight upon contact with liquids. They utilize their gel strength to effectively retain moisture, preventing it from being released. This technology has significantly influenced industries including agriculture for use as a moisture retention and soil enricher and the medical space in sanitation pads, among other applications. It is personal hygiene though, a $145 billion annual global industry, that is the primary application for SAP, constituting over 90% of its annual volume.

While SAP enhances diaper performance, its reliance on petroleum-based inputs inhibits the industry’s transition away from single-use, non-circular, end-of-life practices. The majority of SAP volume worldwide is derived from fossil fuels and lacks biodegradability. Despite its performance attributes, the incumbent SAP is sourced from a finite and rapidly depleting resource, and persists far longer than desired [1]. If the main component of a diaper, the SAP, cannot degrade, investing in other degradable components becomes moot. Consequently, the majority of diapers, along with their petroleum-based SAP, end up in landfills or are incinerated.

According to a 2020 study by the Ellen MacArthur Foundation, 300,000 diapers either enter a landfill or are incinerated -- every minute [2]. And while U.S. consumption represents a fraction of the 200Bn diapers that are manufactured each year, hygiene products are the 3rd largest contributor to limited U.S. landfill space, behind food and paper waste [3].

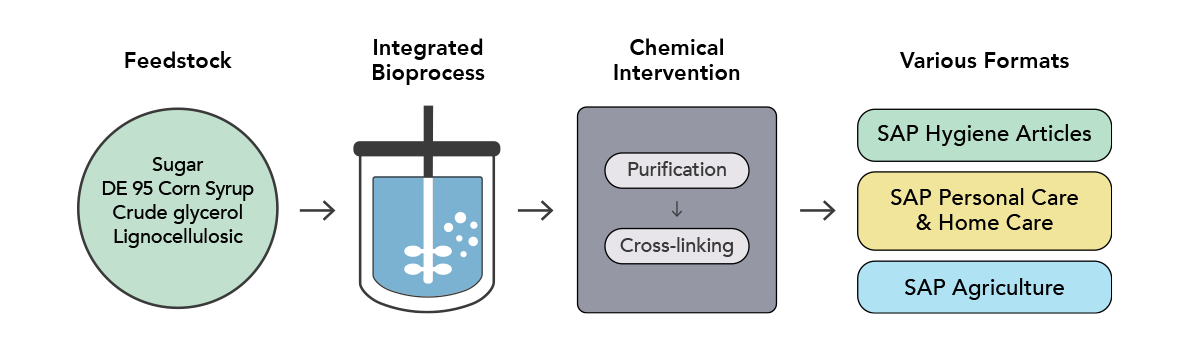

BAYSE™ Bio-Process

With our introduction of BAYSE™, a bio-based, high-performance, biodegradable SAP, ZymoChem can replace the hygiene industry’s petroleum-based, polyacrylic incumbent with a drop-in solution. By optimizing for cost via our patented manufacturing process, BAYSE™ provides the industry with a more sustainable alternative without compromising on price point, availability, or performance.

ZymoChem is excited to be leading the way with a biotech solution to one of the world’s most wasteful items. By tackling the largest and most daunting challenge first -- making baby diapers more sustainable -- we will raise awareness of the benefits of SAP, unlock opportunities for renewable sourcing practices, and promote end-of-life considerations that will benefit industries beyond hygiene. These applications include lawn care, cosmetics, waste water systems, flood prevention, gel packs, and many more.

[1] “End-of-life management of single-use baby diapers: Analysis of technical, health and environment aspect” Science of the Total Environment, 2022

[2] “A Circular Economy for Nappies, and how to implement it locally” Ellen MacArthur Foundation, 2020

[3] “Developments in the use of nonwovens for disposable hygiene products” Advances in Technical NonWovens, 2016